Diesel Generators for Critical Power Supply Ensuring Reliability and Resilience

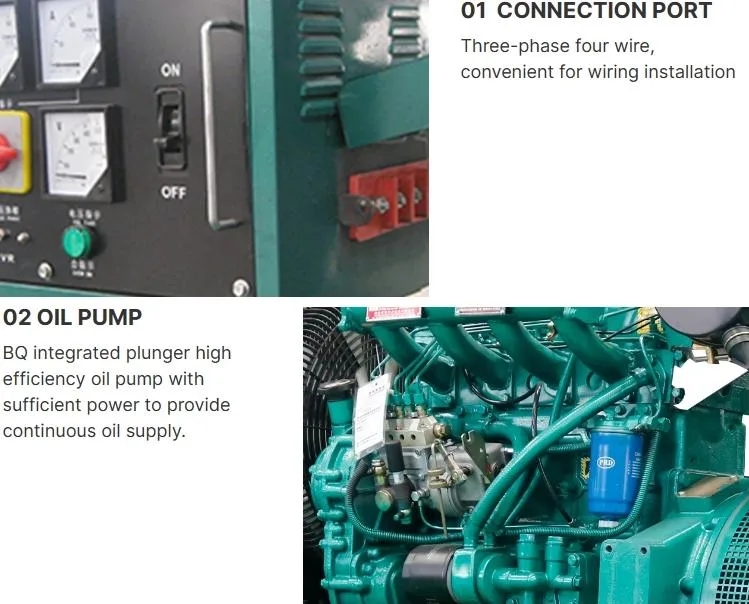

**Title: Diesel Generators for Critical Power Supply: Ensuring Reliability and Resilience** ### Introduction In an era where power is the backbone of modern society, the importance of reliable electricity cannot be overstated. From hospitals and data centers to emergency services and manufacturing plants, many sectors require uninterrupted power supply (UPS) to function effectively. Diesel generators have emerged as a preferred solution for critical power supply needs due to their robustness, efficiency, and reliability. This article delves into the various aspects of diesel generators, exploring their functionality, advantages, applications, and considerations for ensuring optimal performance in critical situations. ### Understanding Diesel Generators A diesel generator is a combination of a diesel engine and an electric generator (often an alternator) that converts diesel fuel into electrical energy. Diesel generators are known for their durability and ability to provide substantial power outputs, making them suitable for various applications, especially in critical power supply scenarios. #### Components of Diesel Generators 1. **Diesel Engine**: The heart of the generator, responsible for converting fuel into mechanical energy. 2. **Alternator**: Converts mechanical energy from the engine into electrical energy. 3. **Fuel System**: Includes the fuel tank, fuel lines, and filters, ensuring a steady supply of diesel fuel to the engine. 4. **Cooling System**: Maintains optimal operating temperatures for the engine and prevents overheating. 5. **Exhaust System**: Channels exhaust gases away from the engine, ensuring safe operation. 6. **Control Panel**: Monitors and controls the generator’s operations, providing information on performance metrics. 7. **Battery**: Powers the starter motor and control systems, ensuring reliable startup. ### How Diesel Generators Work The operation of a diesel generator can be summarized in a few key steps:  1. **Starting the Engine**: The generator's battery supplies power to the starter motor, which cranks the diesel engine. 2. **Combustion Process**: Once the engine is running, air is drawn into the cylinders, mixed with fuel, and compressed. The heat from compression ignites the fuel, causing an explosion that drives the pistons. 3. ** https://www.lkpowerplant.com/product/special-offer-reliable-high-power-200kw-efficient-diesel-generator-set-for-industrial-use/ to Electrical Energy Conversion**: The movement of the pistons turns the crankshaft, which drives the alternator, generating electricity. 4. **Power Distribution**: The electrical energy produced is then distributed through the control panel to power critical loads. ### Advantages of Diesel Generators 1. **Reliability**: Diesel generators are renowned for their reliability and longevity. With proper maintenance, they can run for thousands of hours, making them ideal for critical applications. 2. **Fuel Efficiency**: Diesel engines are more fuel-efficient than gasoline engines, providing more power per unit of fuel consumed. This efficiency is particularly important for extended operation during outages. 3. **Robustness**: Designed to endure harsh conditions, diesel generators can operate in extreme temperatures and challenging environments. 4. **Low Operating Costs**: Although the initial investment may be higher than other generator types, diesel generators often have lower operating costs due to their fuel efficiency and durability. 5. **Scalability**: Diesel generators are available in various sizes and configurations, making them suitable for applications ranging from small backup systems to large industrial power plants. 6. **Performance**: Diesel generators can provide high starting torque, making them capable of handling heavy loads, which is crucial for facilities with significant power demands. ### Applications of Diesel Generators in Critical Power Supply 1. **Healthcare Facilities**: Hospitals and medical centers require uninterrupted power to support life-saving equipment, lighting, and HVAC systems. Diesel generators serve as backup power sources, ensuring that critical functions continue during power outages. 2. **Data Centers**: The digital age has made data centers essential for business operations. Diesel generators provide backup power to maintain server uptime and protect against data loss during outages. 3. **Telecommunications**: Telecom companies rely on diesel generators to keep communication systems operational during power failures, ensuring that emergency services can reach the public. 4. **Industrial Operations**: Manufacturing plants often use diesel generators to support production lines, especially during peak demand periods or outages from the grid. 5. **Emergency Services**: Fire stations, police departments, and emergency response teams utilize diesel generators to power their operations during disasters and emergencies. 6. **Construction Sites**: Temporary power for construction sites is often provided by diesel generators, enabling tools and equipment to operate without reliance on the grid. ### Selecting the Right Diesel Generator When choosing a diesel generator for critical power supply, several factors must be considered: 1. **Power Requirements**: Calculate the total wattage needed for all critical loads, including starting and running watts. This will help determine the generator's size. 2. **Run Time**: Assess how long the generator needs to operate during an outage. Larger fuel tanks provide extended run times, which is essential for prolonged outages. 3. **Noise Levels**: In residential or sensitive environments, noise levels may be a concern. Look for generators designed with sound attenuation features. 4.

1. **Starting the Engine**: The generator's battery supplies power to the starter motor, which cranks the diesel engine. 2. **Combustion Process**: Once the engine is running, air is drawn into the cylinders, mixed with fuel, and compressed. The heat from compression ignites the fuel, causing an explosion that drives the pistons. 3. ** https://www.lkpowerplant.com/product/special-offer-reliable-high-power-200kw-efficient-diesel-generator-set-for-industrial-use/ to Electrical Energy Conversion**: The movement of the pistons turns the crankshaft, which drives the alternator, generating electricity. 4. **Power Distribution**: The electrical energy produced is then distributed through the control panel to power critical loads. ### Advantages of Diesel Generators 1. **Reliability**: Diesel generators are renowned for their reliability and longevity. With proper maintenance, they can run for thousands of hours, making them ideal for critical applications. 2. **Fuel Efficiency**: Diesel engines are more fuel-efficient than gasoline engines, providing more power per unit of fuel consumed. This efficiency is particularly important for extended operation during outages. 3. **Robustness**: Designed to endure harsh conditions, diesel generators can operate in extreme temperatures and challenging environments. 4. **Low Operating Costs**: Although the initial investment may be higher than other generator types, diesel generators often have lower operating costs due to their fuel efficiency and durability. 5. **Scalability**: Diesel generators are available in various sizes and configurations, making them suitable for applications ranging from small backup systems to large industrial power plants. 6. **Performance**: Diesel generators can provide high starting torque, making them capable of handling heavy loads, which is crucial for facilities with significant power demands. ### Applications of Diesel Generators in Critical Power Supply 1. **Healthcare Facilities**: Hospitals and medical centers require uninterrupted power to support life-saving equipment, lighting, and HVAC systems. Diesel generators serve as backup power sources, ensuring that critical functions continue during power outages. 2. **Data Centers**: The digital age has made data centers essential for business operations. Diesel generators provide backup power to maintain server uptime and protect against data loss during outages. 3. **Telecommunications**: Telecom companies rely on diesel generators to keep communication systems operational during power failures, ensuring that emergency services can reach the public. 4. **Industrial Operations**: Manufacturing plants often use diesel generators to support production lines, especially during peak demand periods or outages from the grid. 5. **Emergency Services**: Fire stations, police departments, and emergency response teams utilize diesel generators to power their operations during disasters and emergencies. 6. **Construction Sites**: Temporary power for construction sites is often provided by diesel generators, enabling tools and equipment to operate without reliance on the grid. ### Selecting the Right Diesel Generator When choosing a diesel generator for critical power supply, several factors must be considered: 1. **Power Requirements**: Calculate the total wattage needed for all critical loads, including starting and running watts. This will help determine the generator's size. 2. **Run Time**: Assess how long the generator needs to operate during an outage. Larger fuel tanks provide extended run times, which is essential for prolonged outages. 3. **Noise Levels**: In residential or sensitive environments, noise levels may be a concern. Look for generators designed with sound attenuation features. 4.